23 February, 2026

World's first producer of bio-bitumen

Sun 11 Jan, 2026

Context

- India has become the world’s first country to produce bio-bitumen at a commercial scale, marking a major milesto

- ne in sustainable infrastructure and green technology.

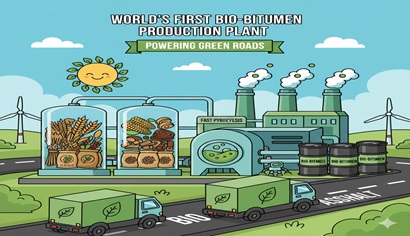

What is Bio-Bitumen?

- Bio-bitumen is an eco-friendly alternative to conventional petroleum-based bitumen used in road construction.

- It is primarily produced from agricultural residues, such as:

-

- Paddy straw (rice stubble)

- Sugarcane bagasse

- Rice husk, etc.

Production Process (Developed by CSIR)

The technology has been developed mainly by CSIR–Indian Institute of Petroleum (IIP), Dehradun, in collaboration with CSIR–Central Road Research Institute (CRRI), New Delhi, after nearly five years of research.

1. Pyrolysis

- Biomass is heated at 400–500°C in the absence of oxygen to obtain bio-oil.

2. Upgrading

- Impurities are removed through processes such as hydrodeoxygenation, imparting properties similar to conventional bitumen (viscosity, thermal stability, durability).

3. Blending

- Bio-bitumen is blended with conventional bitumen at 20–30% (in some cases 10–50%).

- The final product complies with BIS standards (IS 73:2018).

- The technology has been patented, and licenses are being granted to multiple industries.

Key Advantages: Analytical Perspective

1. Environmental Benefits

- 60–70% reduction in greenhouse gas emissions compared to conventional bitumen.

- Provides a sustainable solution to stubble burning, especially in Punjab, Haryana, and Uttar Pradesh, which contributes to severe air pollution in the Delhi-NCR region.

- Promotes Waste-to-Wealth and the Circular Economy.

2. Economic Benefits

- India requires around 5 million tonnes of bitumen annually, of which 40–50% is imported, costing approximately ₹25,000–30,000 crore in foreign exchange.

- Even 15% blending of bio-bitumen could save nearly ₹4,500 crore annually.

- Roads become more durable and cost-effective with lower maintenance and better resistance to rutting and cracking.

- Additional income for farmers, as crop residue becomes a valuable resource instead of waste.

3. Energy Self-Reliance (Atmanirbhar Bharat)

- Reduces dependence on imported petroleum products.

- Supports India’s long-term goals such as Viksit Bharat 2047 and Net-Zero emissions.

4. Technological Status and Global Comparison

- While countries like the Netherlands (lignin-based bio-bitumen), UK, and USA are running pilot projects, India is the first to achieve commercial-scale production.

- A 100-metre trial stretch on NH-40 in Meghalaya has already been completed successfully.

- Plans are underway to construct 1,000 km of pilot roads by 2027.

- Ongoing research focuses on:

-

- 100% bio-bitumen

- Algae-based and wood-based variants

- Versions suitable for extreme climatic conditions